Luiz Antonio Paiva

Agriculture Director of Grupo Cerradinho

Op-AA-28

Reformation of sugarcane agriculture

Reformation of sugarcane agriculture must be viewed as an opportunity to potentialize the production of raw material, adapting and regulating quantitative and qualitative demand to industry and indirectly reducing production cost. If one considers a stable sugarcane plantation, of which 15 to 20% are destined for reformation, the resulting cash flow will be sustainable, allowing for an analysis that does not take financial remuneration into account, making it possible to envisage what would be the ideal moment for undertaking the reformation.

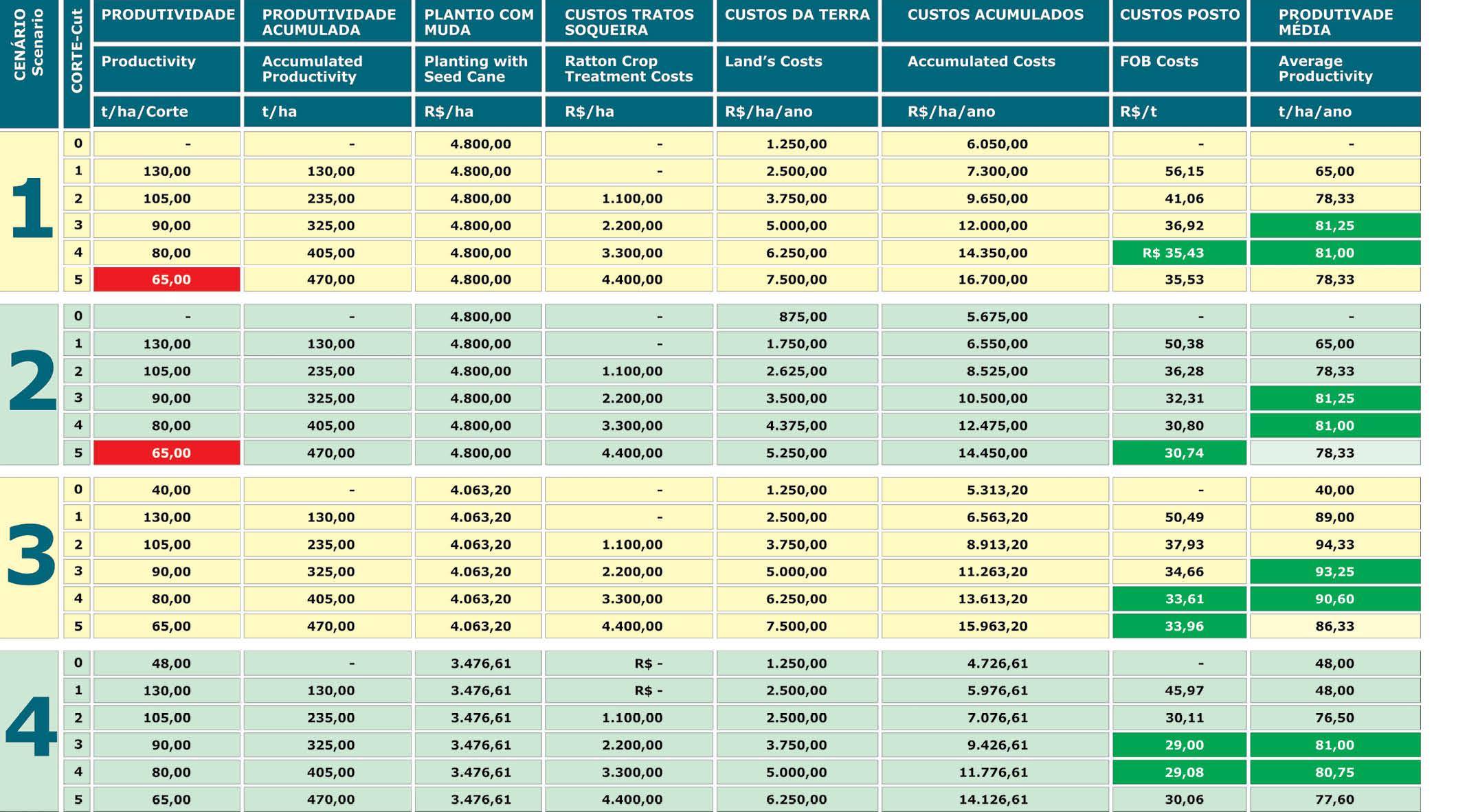

I shall present some charts to show the effect of production costs, excluding harvesting from the decision on the ideal moment to bring about the reformation. In the chart, Scenario 1 shows the simulation of production in traditional sugarcane areas, with more expensive land.

Scenario 2 shows the simulation of production in areas on the agricultural frontier, with less expensive land.Generally, when productivity reaches 50% of the first cut’s production potential, the economic moment for reformation is reached, and from there on sugarcane production costs increase. As one can see in Scenarios 1 and 2, the higher the remuneration of the land, the earlier the economic moment of reformation will be reached.

However, when productivity is less than 60% of the difference of the first cut, one ceases to maximize the production potential of soil that, in this case, is at about 81 t/ha/year.

However, when productivity is less than 60% of the difference of the first cut, one ceases to maximize the production potential of soil that, in this case, is at about 81 t/ha/year.

As one increases the number of cuts, one requires more land to supply raw material. Therefore, in order to increase longevity in a sustainable manner, one must develop a production system in which the high productivity sugarcane plantation is stabilized, which I believe may occur by preserving plant lines of the production system as a whole, which will gain increased momentum once double road harvesting is practiced.

One is experiencing a new phase in agribusiness, leaving behind decades in which people were used to excess supply of commodities, to live a new era, in which demand grows in a world with increasing scarcity of natural resources. One must verticalize production.

To that end, one must develop a production system at minimal implementation and logistics costs, allowing for undertaking large plantings at the right time, and one must be creative to achieve the desired results. In this context, and together with the team, we are engaged in projects such as:

-

Planting of saccharine sorghum in reformation areas, for the sake of incrementing raw material in the offseason (March/April), contributing to sugarcane plantation reformation cost reduction. Due to environmental preservation aspects, one has standardized the direct planting of sorghum in sugar-cane straw;

-

Developing a system of “middles” (MEIOSI), planting two roads of cane and alternating with 8 roads to be planted with sorghum as an “in between” culture, along with the “corners” (CANTOSI) system, in which 20% of the area is destined to planting in delimited areas (blocks);

-

Reduced preparation, with the elimination of terraces and replacement by “bigodes” or water containment boxes, while not leaving the soil uncovered;

-

Verticalization of soil preparation, aiming at exploiting a deeper layer and creation of a traffic zone for agricultural operations as a whole;

- Winter season planting using industrial by-products (vinasse, residual water and filter cake), in which one is capable of producing in excess of 110 t/ha in the first cut.

The Chart shows simulations using the “MEIOSI” system for the application of sorghum, along with the projection for 2012 in Scenario 3 and 2013 in Scenario 4. One notices in the graphs that although the same sugarcane productivity levels are maintained, the addition in the reformation area of a different crop, with the intent of supplying raw material in unfavorable periods for sugarcane, optimizes its use.

One can achieve an increase of 80 t/ha/year in the sugarcane only scenario of 90 t/ha/year of raw material, by adding saccharine sorghum and anticipating the reformation. The cost reduction that occurs due to the increase in production area, which can reach 9%, becomes evident. The verticalization of sugarcane production tends to anticipate the reformation at current productivity levels for the fourth cut. To revert this scenario, it will be necessary to stabilize production at least at 2/3 of the first cut production.