André Elia Neto

Industrial - Environmental Technology Specialist at CTC

Op-AA-27

Reutilization of water

There is a widespread idea among entities associated with hydric and environmental resources, according to which the sugar and ethanol agro-industry is a major consumer of water, which in fact it is, in light of the large quantity of water needed in the industrial processing of sugar and ethanol.

However, this does not imply exaggerated sourcing of water, because for quite some time the industry has been reutilizing water and effluent, thereby meeting the high demand for water in the industrial process. A mill with a 50% sugar and a 50% ethanol production mix, on average, needs 22 m3/t of sugarcane in the industrial process.

In Brazil, sugarcane cultures in general do not require irrigation, which constitutes a major advantage for the industry in terms of sustainability. Only a small portion of the production relies on irrigation, which is widely practiced in Northeastern Brazil and has a tendency to grow in the Midwest.

However, the irrigation practiced is characterized as an “emergency” irrigation, with the application of relatively little water (depth between 100 and 200 mm), but even so the effluent generated in the industrial production of sugar and ethanol is widely used. Average water sourcing for industrial use, which four decades ago was 20 to 15 m3/t of sugarcane, according to surveys conducted by CTC in sugarcane growing regions of Center-Southern Brazil, i.e., 1.85 m3/t of sugarcane (2005 data).

An approximately tenfold reduction in the sourcing rate. Current technologies show a tendency of sourcing about 1.0 m3/t of processed sugarcane, which is the desired, possible and economically feasible rate, which means to say basic engineering’s technological level.

With the coming about of new technologies that will allow using water contained in sugarcane by means of evaporation and reverse osmosis membranes, or other cleaner production technologies, such as the dry cleaning of sugarcane, the sourcing of water for industrial use in the industry may reach levels of 0.5 and less m3/t of sugarcane, in 5 years.

With such rationalization, the sugar-based energy industry is achieving water reutilization rates in its industrial process that reach up to 95%, showing the high reutilization rate of sourced water.

With such rationalization, the sugar-based energy industry is achieving water reutilization rates in its industrial process that reach up to 95%, showing the high reutilization rate of sourced water.

This takes pressure off the quest for new water supply sources, which, combined with the reutilization in agriculture of effluent and residues in the so-called “ferti-irrigation” of sugarcane cultures, thereby also contributing to the preservation of the quality of water springs, which are not burdened with the discharge of residual pollutants possibly originating from treatment systems.

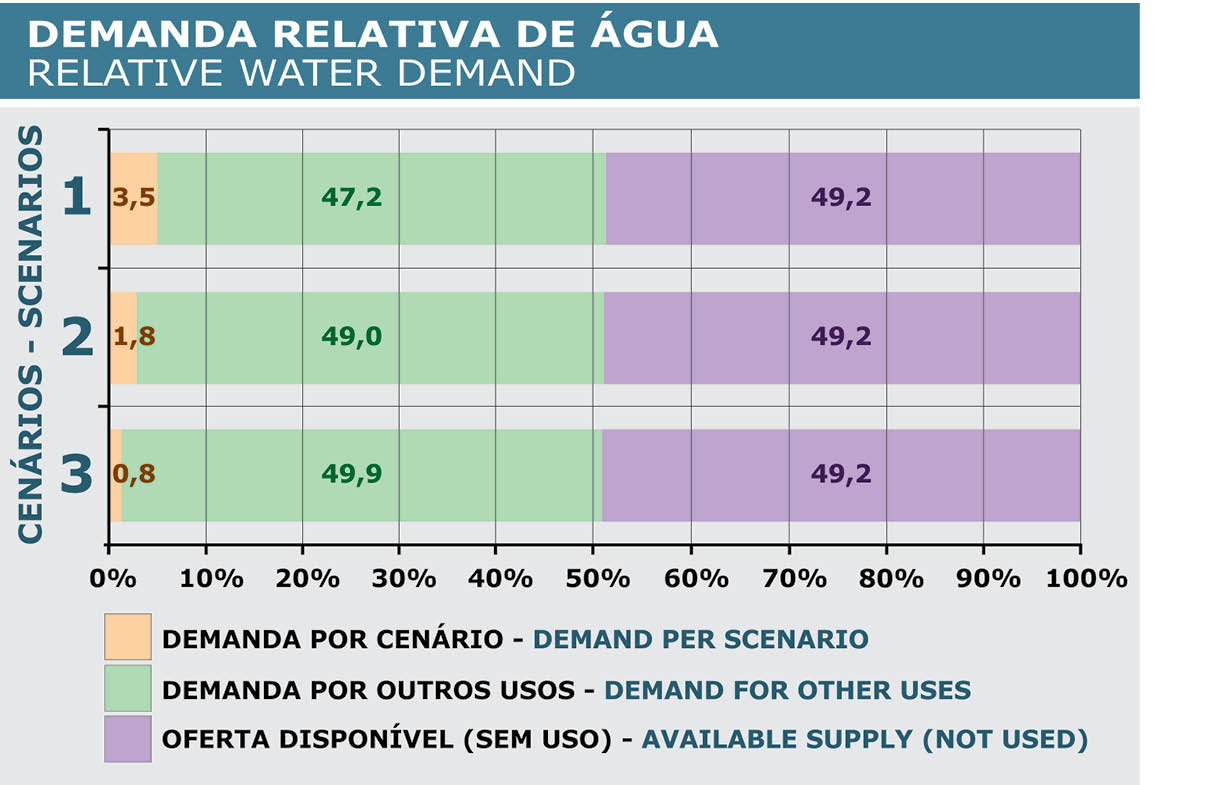

A recently investigation conducted by CTC (Elia Neto, Zotelli and Donzelli, 2010) estimated the sugarcane industry´s demand for water in the units of hydric resources management of the State of São Paulo. The table details three different scenarios of industrial water sourcing during the harvesting period (base harvest 2007/09) – in relation to the minimum supply Q7.10 = 894 m3/s.

The current average demand in this industry, in the State, was 7% of the minimum supply (Q7.10), as shown in scenario 1 (average water sourcing rate of 2 m3/t of sugarcane), in the Relative Water Demand table. It should be noted that in the 90’s, the industry demanded about 13% of the State’s water, and that, notwithstanding the high growth of the sugarcane industry in the last few decades, demand for water decreased by half, with the potential to decrease even more.

Scenario 2 (water sourcing rate of 1 m3/t of sugarcane) is common to most mills in the State of São Paulo (and the Center-South), resulting in a water demand of only 3.5% of the minimum average supply in the State of São Paulo.

With R&D programs aimed at new clean technologies and the reutilization of water, the industry will move towards scenario 3, in which the demand will reach 1.7% of the minimum water supply. A major step for the industry’s sustainability, emphasizing that the State of São Paulo processes about 60% of Brazil’s sugarcane.

Worldwide concern about sustainability is motivating the implementation of environmental indices that seek to assess the sugar-based energy industry’s production chain. The rationalization of the use of water, fostered by legislation and money collecting mechanisms applied to water use by the so-called “Basin Committees”, resulted in the gradual reduction in water sourcing by the industry.

By developing new technologies that will allow using the water contained in sugarcane (about 70% of weight), the impact of using water will consistently decrease, thereby contributing to the sugarcane industry’s sustainability, attenuating conflict with all other industries over water use, in spite of the considerable growth in production recently observed in this important production sector.