Sidnei Brunelli

Director of Empral Piracicaba

Op-AA-27

A mature sector

In the second half of 1973, a new technique in sugarcane juice extraction by crushing arrived in Brazil, bringing about doubts in the minds of some and the opposition of others, along with the lack of cooperation of the main equipment builders at the time, but was widely accepted by sugar mills.

The persons behind this initiative were Jorge Wolney Atala, Pierre Chenu and Deon Hulett, who, based on their fields of activity, combined decisions and work to implement in our mills the techniques already used in Australia and South Africa.

Although these countries were acknowledged for their better extraction methods, their results did not compete with the Cuban methods applied in Florida, in terms of the quantity of crushed cane, which was the main objective of our mill owners. At the time, our mills could hardly crush sugarcane, not to mention their inability to even think about conducting any extraction.

This new technique consisted of: sugarcane preparation with shredder, sugarcane feeding with Donnelly, press roller installation, compound imbibition with hot water and direct return without passing through the cush-cush, utilization of 2” and 1 ½” grooves with a 35º angle and weld application on groove flanks and tops. Over time, the adoption of this proposal was expanded and as an immediate result produced an improvement in extraction, and subsequently, as a side effect, the increase in crushing.

With the implementation of the “Proálcool” program, which fostered the production of ethanol for the purpose of facing the first oil crisis, significant increases in crushing capacity were required, in some cases in excess of 100%. Such demand was met with the same technology that was being implemented, along with the cultivation of the new NA5679 sugarcane variety.

With the implementation of the “Proálcool” program, which fostered the production of ethanol for the purpose of facing the first oil crisis, significant increases in crushing capacity were required, in some cases in excess of 100%. Such demand was met with the same technology that was being implemented, along with the cultivation of the new NA5679 sugarcane variety.

In the words of Engineer José Marcos Lorenzeti: “This variety was a mark that stands-out in agro-industry history due to its agronomic and industrial qualities, with emphasis on its precociousness, which greatly contributed to increase annual production capacity of industrial installations”. This technology contributed to the success of the government’s ethanol production incentive program, given that it did not require significant investments in new crushing mills, allowing to direct investments to distilleries.

Nowadays, with a lot of mileage accumulated on this road and a number of difficulties faced in the process, I stress the success achieved in increasing extraction, along with the volume of crushed cane, through to the cultivation of variety NA5676, which, without our knowing it or requiring it, turned out to be easily crushable.

Nowadays, with a lot of mileage accumulated on this road and a number of difficulties faced in the process, I stress the success achieved in increasing extraction, along with the volume of crushed cane, through to the cultivation of variety NA5676, which, without our knowing it or requiring it, turned out to be easily crushable.

In the early 80’s, this variety had come to represent 50% of the sugarcane planted in the State of São Paulo. However, I must admit I was wrong in predictions of the future presented in a lecture in 2002. I believed the race towards even bigger crushing mills, as opposed to extraction, would be overcome, and that managers would be concerned about supplying qualified labor to the industry, with engineers and technicians specially trained for that intent.

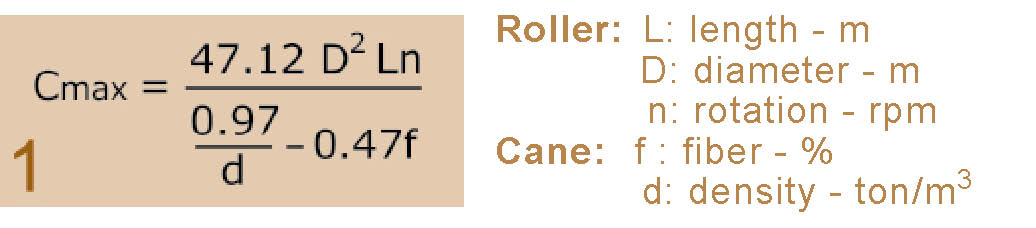

Crushing Capacity: With the new scenario came the need to review traditional, empirical formulas used to calculate the crushing capacity, which no longer suited the technique then employed. Following theoretical and practical studies, we developed a new formula, originally published in Copersucar’s Technical Bulletin 14-81 in 1981, in which:

One can observe that in addition to the crushing mill’s geometric forms (D, L and n), fiber has little influence on the result, actually increasing capacity as it increases. On the other hand, sugarcane density at the bottom of Donnelly is the most determinant item for capacity.

One can observe that in addition to the crushing mill’s geometric forms (D, L and n), fiber has little influence on the result, actually increasing capacity as it increases. On the other hand, sugarcane density at the bottom of Donnelly is the most determinant item for capacity.

Therefore, it is very important to consider the factors that influence density, such as the height of sugarcane in the Donnelly, the morphology of the sugarcane (variety, maturation, kind of fiber, etc.) and vegetal impurities.

This latter factor is extremely important and must be considered when proposing to not burn the sugarcane – impurity content of 8% can reduce crushing by up to 15%.

Therefore, the commonly heard statement whereby crushing decreased because fiber content increased during the crop, is not true. This may happen, but for other reasons that caused sugarcane density to decrease.

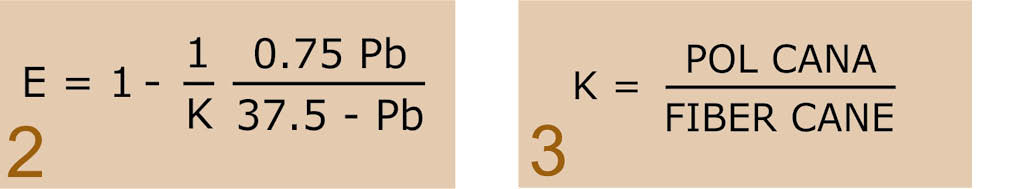

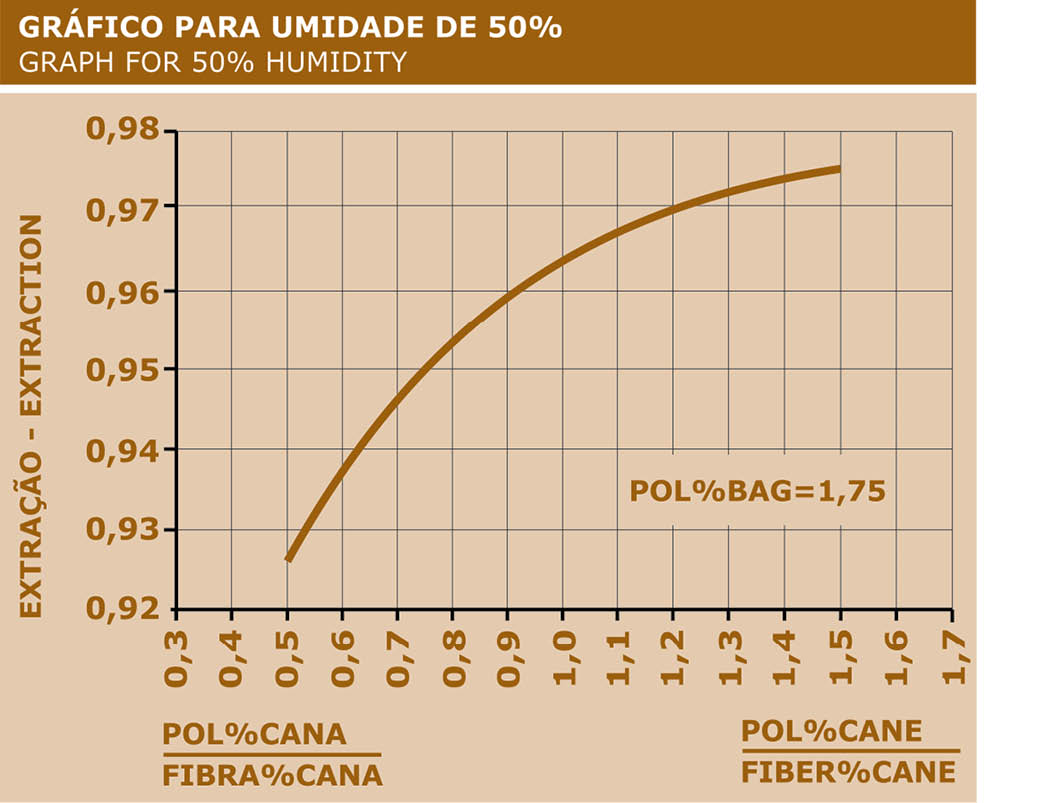

Extraction: The extraction of sugar contained in sugarcane is defined by the Formula: Sugar from cane minus Sugar from bagasse, divided by Sugar from cane, which can be expressed by Formula 2 (for bagasse humidity of 50%). Formula 3 defines the quality of the raw material.

Today’s Mill: We have come a long way since the new techniques arrived in 1973, mainly with relation to the supply of equipment, which allows us to set-up a juice extraction unit in a compact manner, involving few but sturdy and highly reliable equipment units, driven electrically, thereby minimizing maintenance and energy consumption.

As an example, I refer to a chopped cane installation with:

- dois pontos de recepção de cana, compostos por um hilo de 45 toneladas ou mais, um transportador metálico de 2,5 x 25 m e limpeza a seco com processamento da palha;

- a conveyor belt that feeds a chute directly, which in turn, feeds a shredder;

- a Vertical Shredder only, not preceded by a rotor;

- a conveyor belt for shredded cane that feeds the Donnelly of the first mill;

- a set of two tandem mills 1450 x 2500 + four tandem mills 1350x2300.

This installation allows us to crush 1400 TCH or 6 million TC/Crop. We can state that the level reached in this area is no longer that of a developing country.