Gustavo Mockaitis

Professor of the Interdisciplinary Group on biotechnology in agriculture and the environment at the Feagri-UNICAMP

OpAA74

In search of a new biofuel

Vinasse is the largest by-product of ethanol production in terms of volume. For every liter of ethanol produced, 8 to 18 liters of vinasse are produced. Vinasse is the residue from the distillation process of the fermented sugarcane must and consists of a liquid with a high organic load. This by-product is routinely used in the fertigation of sugarcane in producing regions, in order to return part of the nutrients and water used in the production process to the soil.

Although the practice of fertigation brings several benefits, non-compliance with some regulations has already shown that the abuse or mismanagement of fertigation can cause environmental damage that is difficult to address, such as soil salinization and groundwater contamination with vinasse constituents.

One of the ways used in vinasse management is anaerobic digestion, which is a biological waste treatment process widely used for other wastes. However, vinasse processing through anaerobic digestion presents numerous challenges, such as the large volumes produced and the high organic load of vinasse (about 100 times greater than domestic sewage), in addition to the process not being able to eliminate the salinity of this residue.

Another problem is the sugarcane off-season, causing the vinasse production process to be interrupted for about three months, constituting a serious operational problem, since anaerobic digestion is a biological process that takes a lot of time. time to establish itself in a stable and efficient manner.

Another problem is the sugarcane off-season, causing the vinasse production process to be interrupted for about three months, constituting a serious operational problem, since anaerobic digestion is a biological process that takes a lot of time. time to establish itself in a stable and efficient manner.

The anaerobic digestion process was originally developed to mitigate environmental impacts arising from the release of waste with a high organic and nutrient load. The application of the process in the treatment of vinasse is adequate, despite the challenges presented. The anaerobic digestion process transforms organic matter into biogas, which is a mixture of methane and carbon dioxide, in addition to other gases in smaller amounts. In the waste management paradigm, biogas is an issue as methane is a major contributor to global warming, being a greenhouse gas 80 times more powerful than carbon dioxide.

This waste management paradigm exclusively aimed at mitigating environmental impacts is becoming obsolete. Treatment units were commonly oversized and poorly operated, at a great cost to production units. Thus, the need to bring economic viability together with environmental viability becomes clearer, within a broader concept of process sustainability.

In this new paradigm, processes are needed that not only adequately deal with environmental problems, but also transform the waste obtained into a product with added value. In this context, biogas production is an opportunity for energy production, but this application is already widespread. Many industries use anaerobic digestion processes associated with biogas purification processes, in order to produce biomethane (or renewable natural gas, with at least 90% methane content). Even so, many of these industries that produce biogas for energy purposes still use expensive and oversized equipment, in addition to completely outdated operational controls.

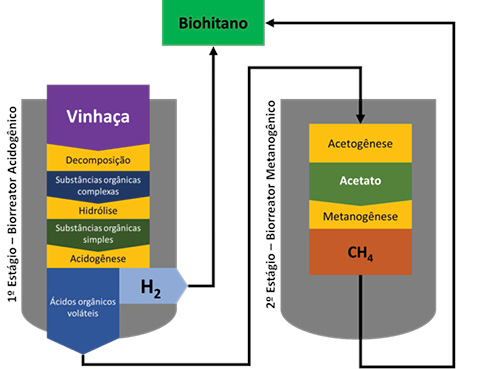

Considering this scenario, our research group proposes a greater advance towards the valorization of vinasse as a raw material for the production of biogas, increasing the energy potential of the biogas produced through the digestion of vinasse. To that end, we are investigating modifications to the anaerobic digestion process to produce a hydrogen-enriched biogas, called bio-hitane.

Hythane is a fuel gas consisting of a mixture of 80% natural gas and 20% hydrogen. The name of this fuel comes from English and emerged as an alternative to natural gas, with the same energy potential as natural gas, but with greater flammability and lower emissions of pollutants. As hythane is originally a gas produced by mixing natural gas with hydrogen from other sources, the name bio-hithane was adopted for the mixture of biomethane and hydrogen obtained by the anaerobic digestion process.

The process of anaerobic digestion occurs naturally in water bodies in the deeper layers, where dissolved oxygen is scarce, being responsible for the production of swamp gas (also known as will-o'-the-wisp, which gave rise to the legend of the boitatá). Anaerobic digestion consists of a series of complex biochemical reactions carried out by numerous anaerobic and facultative microbial communities, which present a synergistic ecological relationship. Despite the complexity of the process, it is possible to identify the steps for converting complex organic matter into simpler molecules.

In general, the process begins with the hydrolysis of complex organic matter that breaks down proteins, fats and carbohydrates into simpler molecules, such as amino acids, fatty acids and saccharides. The molecules produced in the hydrolysis step are then converted into low molecular weight fatty acids (volatile acids), consisting of 6 to 2 carbons. This step is called acidogenesis. These volatile acids are in turn converted to acetate in the subsequent step called acetogenesis.

Finally, this acetate is converted to methane in the final step called methanogenesis. Throughout all stages of this process, carbon dioxide and hydrogen are also produced. However, part of this carbon dioxide and almost all of the hydrogen is consumed by microorganisms to produce both acetate and methane, by microorganisms that consume carbon dioxide, rather than complex organic matter, to grow.

The biological process of hydrogen production is called dark fermentation and is obtained from the inhibition of biochemical processes and selection of microorganisms that consume hydrogen within the anaerobic digestion process. As most hydrogen consuming organisms are acetate and methane producers, the main focus of research is the development of an acidogenic process for the production of hydrogen. Another product of acidogenic processes are also volatile acids, and they can be converted to methane in a process downstream of the acidogenic process.

Thus, our research has two major focal points: to select microorganisms capable of producing hydrogen in a stable and efficient manner; and to develop a two- phase production process for the production of methane and hydrogen. There are still many challenges to be faced, but, once these problems are overcome, a new type of biofuel will compose the energy matrix of the future: sustainable and energy efficient.