Luiz Augusto Horta Nogueira

Centro de Excelência em Eficiência Energética da UNIFEI e Núcleo Interdisciplinar de Planejamento Energético da UNICAMP

OpAA74

Hidrogênio renovável a partir da biomassa: perspectivas no Brasil

Descoberto em 1766, por Cavendish, como um gás combustível formado na reação entre metais e ácidos e batizado como “o formador da água” por Lavoisier, em 1783, o hidrogênio é o elemento químico mais simples e o mais abundante, representando 75% da massa do Universo, mas constitui menos de 1% da massa do nosso planeta Terra, quase sempre associado a outros elementos, como com o oxigênio na água.

O hidrogênio (H2) apresenta propriedades diferenciadas dos demais gases, que podem representar vantagens, como um alto poder calorífico, ou dificuldades, como a baixa densidade (menos de 10% da densidade do ar), alta velocidade de chama e, curiosamente, ser um dos poucos gases que se aquece ao expandir, impondo o seu resfriamento ao abastecer em segurança tanques que devem suportar pressões muito altas, da ordem de 900 atm.

Embora o uso do hidrogênio para fins energéticos tenha sido sugerido há muito tempo, por visionários como Jules Verne, seu alto custo, comparado aos combustíveis fósseis, tem sido um obstáculo para sua difusão nessas aplicações. Não obstante, na atualidade, são importantes as aplicações industriais do hidrogênio, especialmente no refino do petróleo e na produção de amônia, com uma demanda global de cerca de 75 milhões de toneladas anuais, produzidas basicamente a partir de gás natural e do petróleo, com a significativa emissão de CO2 fóssil e, portanto, elevando o efeito estufa na atmosfera. Trata-se, assim, de um hidrogênio indesejável.

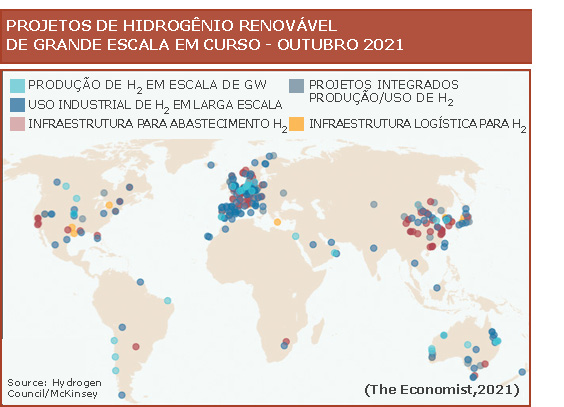

Embora o uso do hidrogênio para fins energéticos tenha sido sugerido há muito tempo, por visionários como Jules Verne, seu alto custo, comparado aos combustíveis fósseis, tem sido um obstáculo para sua difusão nessas aplicações. Não obstante, na atualidade, são importantes as aplicações industriais do hidrogênio, especialmente no refino do petróleo e na produção de amônia, com uma demanda global de cerca de 75 milhões de toneladas anuais, produzidas basicamente a partir de gás natural e do petróleo, com a significativa emissão de CO2 fóssil e, portanto, elevando o efeito estufa na atmosfera. Trata-se, assim, de um hidrogênio indesejável. No contexto da atual transição energética global, com a substituição das fontes energéticas fósseis por renováveis, atendendo a objetivos de descarbonização das matrizes energéticas, incremento da segurança energética e racionalidade econômica, o hidrogênio que todos buscam é o hidrogênio verde, isto é, o hidrogênio produzido a partir de energia renovável, substituindo o hidrogênio “sujo” nos usos como matéria-prima e abrindo novos mercados no setor energético, como combustível em fornos e caldeiras em indústrias, em sistemas de armazenamento energético (crescentemente necessários devido à expansão da geração intermitente das centrais eólicas e solares) e no setor de transporte, onde o óleo diesel, a gasolina e o querosene ainda dominam amplamente. Nessa direção, diversas agências projetam uma grande expansão da produção de hidrogênio renovável, exigindo investimentos superiores a 200 bilhões de dólares, para atender a uma demanda prevista da ordem de 550 milhões de toneladas em 2050. A figura abaixo indica os projetos atualmente em curso, especialmente na Europa e Ásia.

Processos para produção de hidrogênio renovável: As rotas tecnológicas mais promissoras para produção do hidrogênio renovável são:

a) a partir da eletricidade, mediante o processo de eletrólise, no qual a água é separada em seus componentes. É o processo mais maduro e amplamente adotado nos projetos atualmente em implantação, nos quais a eletricidade deverá ser produzida a partir de fontes renováveis;

b) a partir da biomassa, por três alternativas: (1) a reforma do biometano (CH4), principal componente do biogás, (2) a reforma do etanol (C2H6O), processos endotérmicos similares e tecnologicamente maduros, nos quais com catalisadores adequados e água, a energia desses biocombustíveis permite manter reatores (reformadores) a temperaturas entre 650 a 900 C , e produzir correntes com hidrogênio, que pode ser purificado em teores elevados, e (3) em processos de gaseificação de biomassa sólida de baixo custo, produzindo gases com teores de hidrogênio mais baixos, mas que também podem ser purificados. Esses últimos processos se encontram em desenvolvimento, com resultados promissores, entretanto, sem ainda terem demonstrado sua viabilidade econômica.

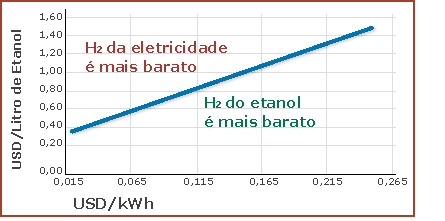

b) a partir da biomassa, por três alternativas: (1) a reforma do biometano (CH4), principal componente do biogás, (2) a reforma do etanol (C2H6O), processos endotérmicos similares e tecnologicamente maduros, nos quais com catalisadores adequados e água, a energia desses biocombustíveis permite manter reatores (reformadores) a temperaturas entre 650 a 900 C , e produzir correntes com hidrogênio, que pode ser purificado em teores elevados, e (3) em processos de gaseificação de biomassa sólida de baixo custo, produzindo gases com teores de hidrogênio mais baixos, mas que também podem ser purificados. Esses últimos processos se encontram em desenvolvimento, com resultados promissores, entretanto, sem ainda terem demonstrado sua viabilidade econômica. De forma preliminar, comparando os custos de produção do hidrogênio em eletrolisadores e mediante a reforma de etanol, sem considerar os investimentos em equipamentos e instalações (certamente mais elevados na eletrólise) e levando em conta apenas os custos dos insumos (eletricidade e etanol), é possível obter a curva de paridade indicada na Figura abaixo. Em síntese, o etanol é competitivo na produção de hidrogênio, considerando os valores correntes da energia elétrica, que, apenas a valores muito baixos, é a melhor opção.

Iniciativas no Brasil para produzir hidrogênio envolvendo biomassa: Para o Brasil, com boa dotação de recursos naturais e domínio das tecnologias bioenergéticas, a biomassa se configura como uma alternativa de efetivo potencial na economia do hidrogênio e que vem sendo objeto de iniciativas tão inovadoras como interessantes, apresentadas a seguir.

Hidrogênio a partir da reforma de etanol. A empresa Hytron, de Sumaré, São Paulo, fundada em 2003 como um spin-off da Unicamp, foi incorporada, em 2020, pelo grupo NEA Neuman & Esser, de Aachen, Alemanha, reforçando sua atuação na integração de sistemas com foco em hidrogênio. Entre seus produtos, com tecnologia própria, a Hytron oferece uma linha de sistemas de produção de hidrogênio por reforma de etanol, com capacidade de até 750 kg H2/dia, consumindo 7,65 litros de etanol e 2,35 kWh por kg de hidrogênio produzido.

Veículos elétricos com células de combustível a hidrogênio gerado por reforma de etanol a bordo. A montadora Nissan desenvolve, desde 2016, com entidades brasileiras e japonesas, veículos elétricos nos quais a eletricidade é gerada em células de combustível a óxido sólido, alimentadas com hidrogênio produzido no próprio veículo, mediante a reforma catalítica de etanol. Os testes mostraram a viabilidade técnica, com o protótipo montado em uma van fazendo cerca de 30 km por litro de etanol. O projeto continua em desenvolvimento, visando melhorar o desempenho e reduzir o volume ocupado pelo reformador. Outras montadoras demostraram interesse nessa solução para a eletrificação de seus modelos.

Produção de amônia verde utilizando hidrogênio produzido por reforma de biometano gerado na biodigestão da vinhaça de etanol. Em 2021, as empresas Raízen e Yara estabeleceram um consórcio para a produção de amônia verde, utilizando o hidrogênio produzido a partir do biometano resultante do biogás de vinhaça. Uma caraterística interessante desse projeto é que o biometano será produzido em Piracicaba, injetado no gasoduto Gasbol e transportado até Cubatão, no litoral paulista, onde será usado para produzir hidrogênio e, daí, amônia com baixa pegada de carbono.

Apenas como exercício, considerando que 4,85 m³ de biometano produzem 1 kg de hidrogênio, que, por sua vez, combinado com nitrogênio, dá origem a 5,67 kg de amônia, a estimativa recente da Associação Brasileira do Biogás de uma produção de 2,2 milhões de m³/dia biometano no Brasil, em 2027, poderá significar da ordem de 940 mil toneladas anuais de amônia verde, 40% acima do consumo nacional aparente de amônia fertilizante em 2017.

Ainda que essas notas se dediquem ao hidrogênio com origem na biomassa, cabe mencionar que avançam outras rotas conectando hidrogênio renovável e biomassa. Como um bom exemplo, o projeto Omega Green, em implantação pela BSBios Paraguay, com investimentos da ordem de um bilhão de dólares, vai utilizar hidrogênio produzido com hidroeletricidade, farta no país vizinho, e óleos vegetais paraguaios para fabricar diesel verde (HVO) e biocombustível aeronáutico renovável (SAF), em volume equivalente a mais de um bilhão de litros por ano, em grande parte para exportar. Empresas brasileiras estão iniciando projetos nesse rumo.

Concluindo...

O hidrogênio não é nem deve ser encarado como uma nova fonte de energia. O hidrogênio é, de fato, um vetor energético, quem sabe uma promissora tecnologia para transporte de energia, capaz de carregar essa “capacidade de transformar” que chamamos energia. Apresenta propriedades singulares e, quando produzido com baixa pegada de carbono, poderá ser um componente relevante da transição energética global, ampliando o espaço das energias renováveis e sustentáveis.

Existem desafios técnicos e econômicos a superar, mas o forte interesse de alguns países e empresas no seu desenvolvimento está criando condições propícias para a efetiva criação de uma nova indústria energética, voltada para a produção e o uso de hidrogênio.

Nesse mundo que está chegando, a bioenergia encontra novas e relevantes oportunidades, como procuramos sinalizar nessas notas. Emprestando alguns cálculos do Daniel Lopes, da NEA Hytron, que considerou os vários vetores energéticos que a cana-de-açúcar é capaz de fornecer, etanol 1G e 2G, biogás e bioeletricidade, cada tonelada de cana é capaz de produzir 17,8 kg de hidrogênio.

Assim, apenas especulando, os 654 milhões de toneladas de cana que o Brasil colheu na safra 2020/21 poderiam, em tese, produzir 11,6 milhões de toneladas de hidrogênio, cuja produção por eletrólise consumiria 568 TWh, 14% acima do consumo nacional de energia elétrica observado em 2022. Em vista disso, será que há espaço para a biomassa na economia do hidrogênio?