Milas Evangelista de Sousa

Diretor da Renovar Sustentabilidade

OpAA74

Tecnologia da Bioenergia com Captura e Armazenamento de Carbono agrega mais valor ao etanol

A Lei 13.576/2017, que instituiu o RenovaBio, define uma bonificação de até 20% na nota de eficiência energética ambiental para o produtor que comprove ter pegada de carbono negativa no ciclo de vida de produção do biocombustível. Isso pode significar até 20% mais CBIOs emitidos e mais receita gerada para o produtor. Atualmente, os produtores de etanol mais eficientes apresentam intensidade de carbono da ordem de 16g CO2e/MJ. Como, então, tornar esse número negativo e receber a bonificação na emissão dos CBIOs?

Ganhos incrementais por meio de aperfeiçoamentos nos processos produtivos nas áreas agrícola e industrial dificilmente levarão à pegada negativa de carbono. Um caminho promissor é a introdução da tecnologia de captura e estocagem geológica de carbono na produção bioenergética, conhecida pela sigla BECCS (Bioenergy with Carbon Capture and Storage).

Enquanto o CCS (Carbon Capture and Storage) mitiga as emissões de CO2 em indústrias dependentes de energias fósseis, como as termelétricas a carvão ou a gás e as siderúrgicas, o modelo BECCS promove a efetiva remoção de CO2 da atmosfera. Por isso, ele é uma das tecnologias centrais para atingir as metas de neutralidade de carbono, com as quais as principais economias do mundo estão se comprometendo. O IPCC (International Panel on Climate Change) estima ser necessária a implantação de projetos de BECCS para remover 328 bilhões de toneladas de carbono entre os anos 2020 e 2100, mais do que será possível com o plantio de novas áreas florestais, estimado em 252 bilhões tCO2 no mesmo período.

Resumidamente, com a tecnologia de CCS, o CO2 resultante da queima de combustíveis fósseis, que seria emitido para a atmosfera, é capturado e injetado de volta nas rochas sedimentares de onde ele saiu, que abrigam naturalmente as reservas de petróleo, gás natural ou carvão. Ela vem sendo usada há mais de 40 anos na indústria do petróleo para injetar o CO2 obtido da purificação do gás natural em campos produtores e aumentar a recuperação de petróleo. O processo retém parte do CO2 na rocha reservatório, mas seu principal objetivo não é a redução de emissões de CO2, e sim o aumento da produção de petróleo.

O primeiro projeto de CCS exclusivamente para a redução de emissões de CO2 foi desenvolvido no campo de gás de Sleipner pela estatal norueguesa de petróleo Equinor e entrou em operação em 1996. Dos quase 30 projetos de CCS operando em escala comercial no mundo, no fim de 2021, mais de 70% eram de recuperação avançada de petróleo, e os demais visavam à redução de emissões.

Dentre eles há um projeto de BECCS, implantado na usina de etanol de milho da ADM, em Decatur, Illinois. Com capacidade de injetar 1 milhão de toneladas de CO2 por ano desde 2017, ele foi desenvolvido com suporte financeiro do governo americano para demonstrar a viabilidade da tecnologia em escala comercial.

A tecnologia de CCS tem três componentes principais: a captura, o transporte e a estocagem. A captura é feita nas fontes estacionárias de CO2, onde ele é separado, a alto custo, dos outros gases emitidos na queima dos combustíveis fósseis. O CO2 capturado é transportado por dutos ou, eventualmente, navios (em caso de projetos marítimos), para um ponto geologicamente adequado de injeção numa bacia sedimentar. A tecnologia de construção e operação dos dutos e navios é a mesma usada no transporte de gás natural, amplamente dominada pela indústria de petróleo.

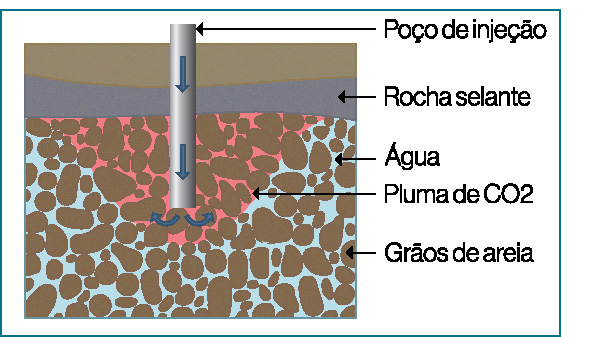

As bacias sedimentares recobrem boa parte de todos os continentes. No Brasil, existem mais de 6 milhões de km2 de bacias sedimentares, dos quais 4,9 milhões de km2 estão em terra, e o restante, na plataforma continental. A estocagem geológica de carbono exige duas condições primordiais: a existência de rochas porosas preenchidas por água salgada (aquíferos salinos); e, imediatamente acima delas, uma camada de rocha impermeável selante.

Devido à necessidade de comprimir o CO2 para redução de seu volume e elevação de sua densidade, a injeção é feita a mais de 800 metros de profundidade, onde a pressão nos poros das rochas é suficiente para manter a pressão do CO2 injetado. O CO2 injetado no aquífero salino desloca lateralmente a água da formação e tende a subir com o tempo, por causa da sua densidade menor. Essa trajetória ascendente é impedida pela rocha selante, formando-se, então, uma pluma de CO2 no entorno do poço de injeção, que fica totalmente contida na rocha reservatório e tende a se estabilizar com o tempo, inclusive com a mineralização de parte do seu conteúdo por interações químicas com a água da formação.

A grande vantagem competitiva da indústria de etanol é que o CO2 formado nas dornas de fermentação tem pureza da ordem de 98%. Assim, é preciso apenas sua compressão e desidratação para posterior transporte até um local geologicamente propício para injeção.

A grande vantagem competitiva da indústria de etanol é que o CO2 formado nas dornas de fermentação tem pureza da ordem de 98%. Assim, é preciso apenas sua compressão e desidratação para posterior transporte até um local geologicamente propício para injeção.Considerando o baixo custo da captura e o fato de que boa parte das usinas de etanol de cana se localiza na bacia sedimentar do Paraná, parece haver o match perfeito para a implantação de projetos BECCS nessa área. Não há nenhum grande desafio tecnológico no processo de compressão e desidratação do CO2, que usa tecnologias amplamente dominadas pela indústria do petróleo. Por outro lado, estudos geológicos precisam definir os locais e profundidades onde as condições são adequadas para a injeção segura e permanente de CO2. Importante realçar que os projetos devem contar com um efetivo sistema de monitoramento para demonstrar que o CO2 injetado não migrará da rocha reservatório para a superfície, o que invalidaria a obtenção de créditos de carbono.

A geração de receita para a remuneração do projeto vai depender das condições de preço do mercado de carbono, seja ele regulado (RenovaBio) ou voluntário. Nos EUA, o governo federal criou um incentivo de US$ 50 por tonelada de carbono, que, recentemente, foi aumentado para US$ 85, o que provocou o surgimento de vários projetos, em especial na indústria de etanol. No Brasil, o incentivo é a bonificação de 20% na emissão de CBIOs.

Um problema sério é a inexistência de um marco legal que defina aspectos relevantes para projetos de CCS, como o direito de acesso e exclusividade de uso do espaço poroso (rocha reservatório) e o direito à emissão de créditos de carbono, dentre outros pontos. Há uma minuta de projeto de lei gerada no âmbito do ProBioCCS (Programa Combustível do Futuro), em aprovação no MME para envio posterior ao Congresso, e, no Senado, uma proposta de regulação apresentada em maio pelo senador Jean Paul Prates (PT), que está na Comissão de Infraestrutura.

A implantação do BECCS na indústria de etanol no Brasil requer a coordenação de esforços do setor junto ao Governo Federal, para que tenhamos, o quanto antes, uma política de CCS no País e sua regulamentação infralegal, destravando a implantação de projetos e a criação de um novo mercado de serviços, bem como gerando receita adicional para os produtores e contribuindo de forma decisiva para o combate às mudanças climáticas com a remoção de carbono da atmosfera.