Antonio Alberto Stuchi

Consultor especialista em tecnologias do setor sucroenergético

OpAA74

Potencial de hidrogênio do setor sucroenergético

O hidrogênio (H2) é o mais simples e mais comum elemento de todo o universo. Ele possui a maior quantidade de energia por unidade de massa que qualquer outro combustível conhecido, aproximadamente 120.700 quilojoules por kg, cerca de três vezes mais calor que o petróleo. Quando resfriado ao estado líquido, o hidrogênio de baixo peso molecular ocupa um espaço equivalente a 1/700 daquele que ocuparia no estado gasoso, sendo possível, então, o seu armazenamento e transporte.

Pesquisas de desenvolvimento em relação ao H2 estão sendo realizadas em todo o mundo com o objetivo de diminuir principalmente os custos de sua produção, armazenagem, transporte, segurança e infraestrutura. A maior parte do hidrogênio produzido ainda é utilizado como matéria-prima na fabricação de produtos como os fertilizantes, conversão de óleo líquido em margarina, processo de fabricação de plásticos e no resfriamento de geradores e motores. Entretanto, as pesquisas sobre o hidrogênio estão rapidamente sendo concentradas na geração de energia elétrica e de água pura através das “Células a Combustível” (CaC), que podem prover energia para equipamentos estacionários ou móveis.

Chama a atenção principalmente o fato de o hidrogênio ser o elemento químico mais básico e abundante na natureza e que sua combustão é totalmente limpa. Existe um movimento em favor de uma economia baseada no hidrogênio, e não mais no petróleo.

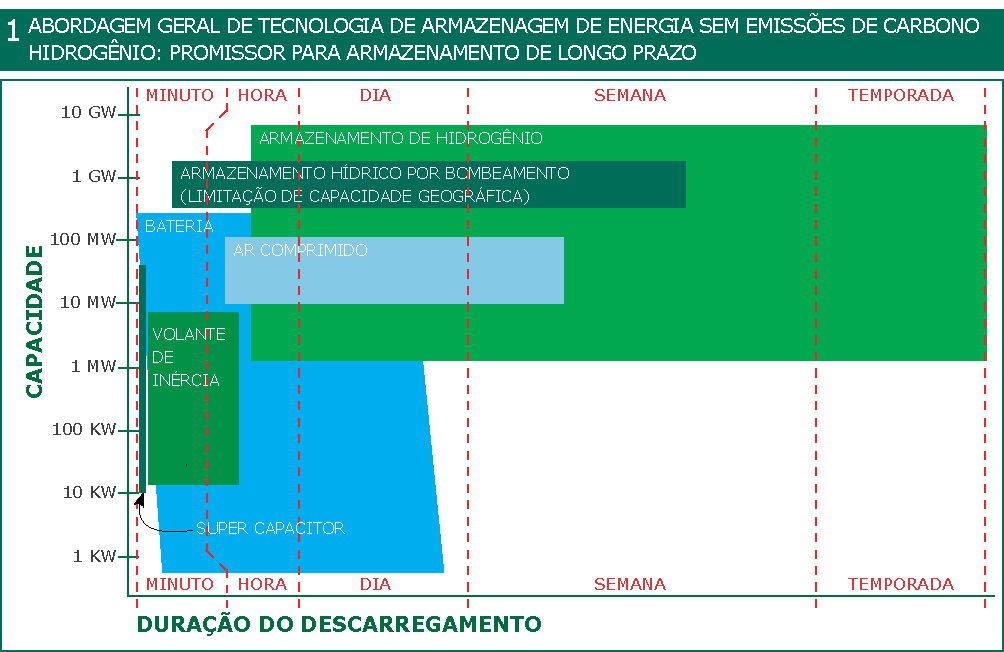

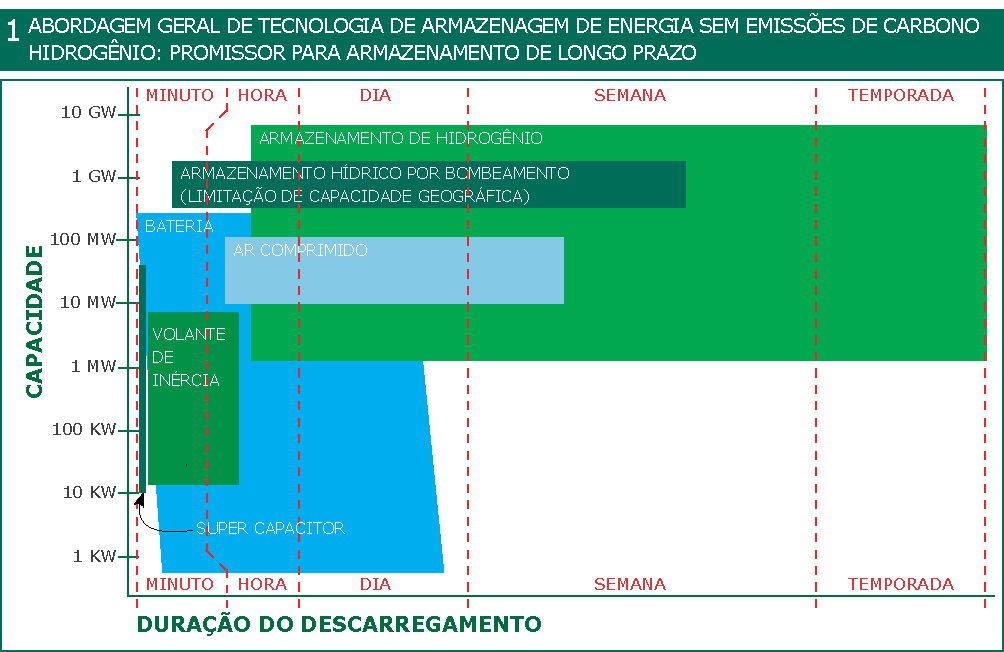

A tecnologia baseada no hidrogênio é, sem dúvida, muito promissora, e ele será o vetor energético do futuro. O pleno aproveitamento da energia produzida por fontes intermitentes, como eólica e fotovoltaica, depende da utilização de acumuladores de energia. A densidade de energia das baterias ainda é muito baixa, e o hidrogênio pode ser uma alternativa para o armazenamento da energia com densidade mais alta. Veja detalhes no gráfico 1.

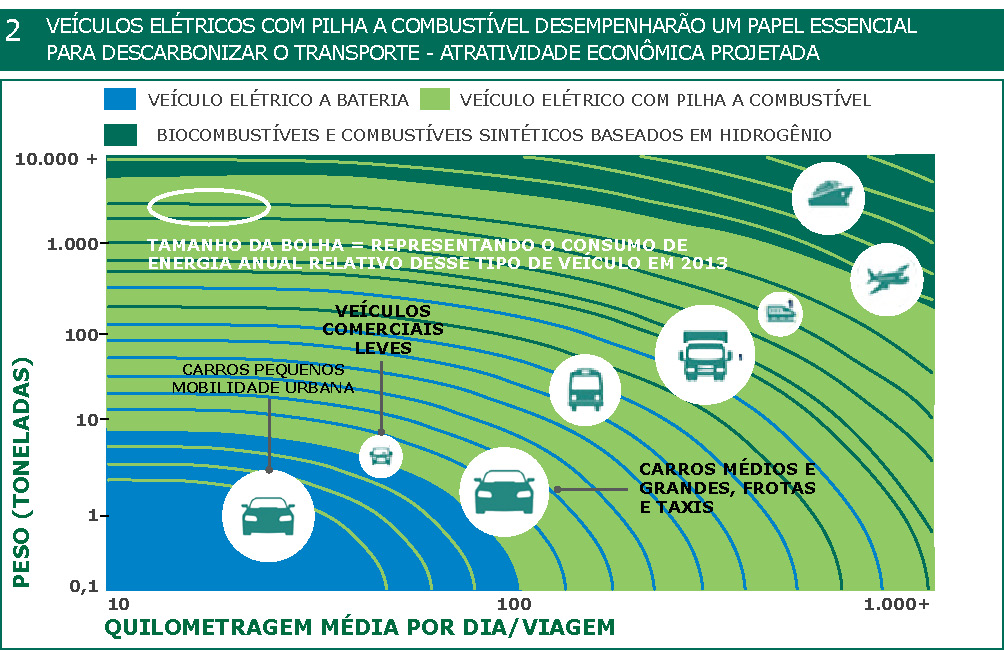

As novas demandas de mercado, principalmente para o acionamento de veículos de transporte terrestre, vêm indicando que as plataformas elétricas irão ocupar um grande espaço, principalmente pela simplicidade e custos dos veículos elétricos e pela não emissão local de poluentes CO2, C0, NOx, SOx.

Porém alguns problemas se apresentam como a fonte que produz a energia a ser consumida, infraestrutura de distribuição e principalmente baterias, que vão ter seu tamanho associado à potência demandada pelos veículos (densidade de energia) e materiais para construção.

Para veículos de até 10 toneladas, com raio médio de 100 km/dia, provavelmente a solução bateria recarregável será a recomendada. Para veículos de até 10.000 t e raio médio de até 1.000 km/dia (carros grandes, caminhões e trens), a solução provável será o uso de hidrogênio com células de combustível. Para tonelagens e distâncias maiores (aviões e navios), provavelmente o uso direto de biocombustível será a recomendada. Veja detalhes no gráfico 2.

O hidrogênio deve ter uma grande participação na matriz energética em pouco tempo e pode ser produzido através de fontes renováveis, como energia eólica e fotovoltaica, que são intermitentes e produzidas não necessariamente próximas aos locais de consumo. Esses problemas podem ser superados com instalação de armazenagem e infraestrutura de distribuição, que, normalmente, demandam altos investimentos.

A produção de hidrogênio a partir de biomassa superaria os problemas de armazenagem e poderia utilizar a infraestrutura de distribuição de combustíveis existente hoje. O etanol, assim como o biometano, metanol e amônia, podem ser utilizados como “vetores estáveis” de hidrogênio, que, depois de passar por um processo chamado reforming, podem liberar o hidrogênio e a água. Dessa forma, podemos abastecer diretamente o veículo com etanol e obter o hidrogênio através de um reformador instalado no próprio veículo ou utilizar reformadores maiores instalados em postos de combustível, que abasteceriam diretamente os veículos com hidrogênio.

Considerando o portfólio de produtos do setor sucroenergético, podemos produzir hidrogênio a partir do etanol, da eletricidade excedente e do biometano produzido a partir de torta e vinhaça.

Adotando o cenário de produção da safra 2021/22 podemos calcular o potencial de hidrogênio deixando intacta a produção de açúcar. Supondo uma safra de 660 milhões de toneladas de cana, com 41 milhões de toneladas de açúcar e 31,5 milhões m³ de etanol (base anidro) e 380 milhões de m³ de vinhaça.Para avaliação de potencial, podemos considerar essas usinas otimizadas para consumo de vapor de processo na ordem de 450 kg vapor por tonelada de cana e utilizando caldeiras de alta pressão (67 bar 500C), o que permitiria uma produção excedente de 33.000 GWh de energia elétrica.

A conversão do etanol, biometano da vinhaça e eletricidade excedente resultariam numa produção de 5,42 milhões de toneladas de hidrogênio. Podemos acrescentar 1,79 milhão de toneladas de H2 a esse potencial, proveniente do etanol de segunda geração (2G). Essa produção vem da palha, observando a limitação do uso de 50% do potencial para preservar os benefícios agronômicos da cobertura do solo.

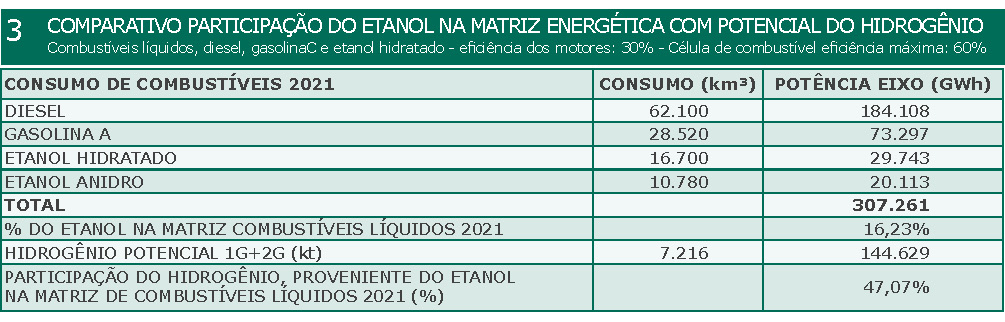

No total, o potencial é de 7,2 milhões de toneladas de H2 (11,9 kgH2/t cana ou 0,82 tH2/ha), podemos, então, fazer uma comparação da participação na matriz energética com o que representa hoje o etanol.

O etanol representa aproximadamente 16% do consumo de energia dos combustíveis líquidos no Brasil, considerando o potencial energético e não simplesmente o volume. Aproveitando o potencial de hidrogênio da produção de cana instalada hoje, essa participação passaria a representar 40% da energia consumida, basicamente pelo fator de aumento de eficiência na produção de energia pelas células de combustível.

Se a cana-de-açúcar for utilizada somente para a produção de etanol e energia, o potencial de produção de hidrogênio sobe para 16,6 kgH2/t cana (1,2 tH2/ha). Para que a matriz de combustível líquido seja 100% a hidrogênio, necessitaríamos de 480 milhões de toneladas de cana, ou seja, uma expansão de 6,5 milhões de hectares.

Obviamente, essa expansão é muito grande, mas, se considerarmos aumento de eficiência na produção de cana-de-açúcar, ou mesmo uso de variedades que aumentem a produção por hectare, mesmo que direcionada à biomassa, a participação dos combustíveis renováveis vai crescer. Outro ponto a se observar é que o etanol pode funcionar bem como ”Vetor de hidrogênio”, evitando investimentos pelo uso da infraestrutura de distribuição e estocagem existentes hoje.