José Aurélio Silvestre Bezerra

Director of AGTech

Op-AA-27

Sugar drying technology

Drying sugar is done to remove the humidity retained by the crystals following centrifugation, to allow for it to be processed, transported and stocked for future use. Humidity directly affects the product’s life cycle. Humidity retained in the sugar crystals is characterized by three different mechanisms:

- External humidity: this is the water present in the concentrated syrup layer, which is distributed over the crystals’ entire surface. This layer is always present as a supersaturated condition. It will depend on crystal size, purity of the mother liquor, the crystallization mechanism, and on how carefully it is performed, and also on how crystallization takes place.

It is also a direct function of washing the sugar in the centrifuges. Depending on the washing process, it will show values varying from 1.0% to 0.3%. It is important the washing be done in a correct manner and within an extremely critical time period, otherwise the sugar will dissolve to a great extent with little purge efficiency. If the water evaporates and is removed quickly, this will result in serious problems for the sugar’s quality, because a crystallized superficial layer of sugar will form.

- Internal humidity: this is the water inside the crystals. It takes more time to bring it to the crystals’ surface, by means of a diffusion-like process. Normally, this time is not available in the dryers. Thus, a fraction of the water can be removed later under certain conditions. It is this fraction of water that causes major problems in forming agglomerates, lumps and for the subsequent dissolution of sugar during storage.

It is also more often retained when one operates with high temperature hot air or reduced air flow. Unfortunately, these two conditions are quite common in most drying plants, mainly due to the increase in crushing and sugar production, without the corresponding increase in dryer capacity. Thus, the air temperature increases and one operates with the same ventilators and dryer, greatly reducing retention time and the relation air volume/sugar.

- Crystallization water: water associated with the saccharose molecule. It is part of the structure that cannot be removed. It does not affect sugar quality. Final humidity control after drying is usually done by analyzing the humidity in the oven. This analysis is incomplete and error-prone because it only measures free water, not showing the internal water.

Adequate operational conditions: one of the most critical factors in measuring is the size and variation in quality of the crystals. Large, uniform crystals, with a low variation coefficient and reduced content of inclusions greatly improve drying efficiency. Fine, irregular crystals, with many inclusions, conglomerates and excessive dust will result in poor dryer performance and an inadequate outcome.

The second phase consists of adequately controlling centrifugation. The volume of water, its correct distribution through sprayers. so as to uniformly spread it over the basket surface, the right temperature and the proper minimum time needed should remove the syrup layer to the greatest extent, without too much of the sugar dissolving.

The second phase consists of adequately controlling centrifugation. The volume of water, its correct distribution through sprayers. so as to uniformly spread it over the basket surface, the right temperature and the proper minimum time needed should remove the syrup layer to the greatest extent, without too much of the sugar dissolving.

To use two washing periods is normal. The first washing intends to dilute the mother liquor and assure its efficient removal without dissolving the sugar. The second washing should be done with the centrifuge still accelerating, so as to achieve the complete removal of the produced syrup.

This washing, when done too late, tends to produce sugar with high humidity and the formation of agglomerates. The use of vapor to optimize the drying and increase the dryer capacity is recommended, but at a low temperature. An interesting application is to vary the vapor volume between the two washings.

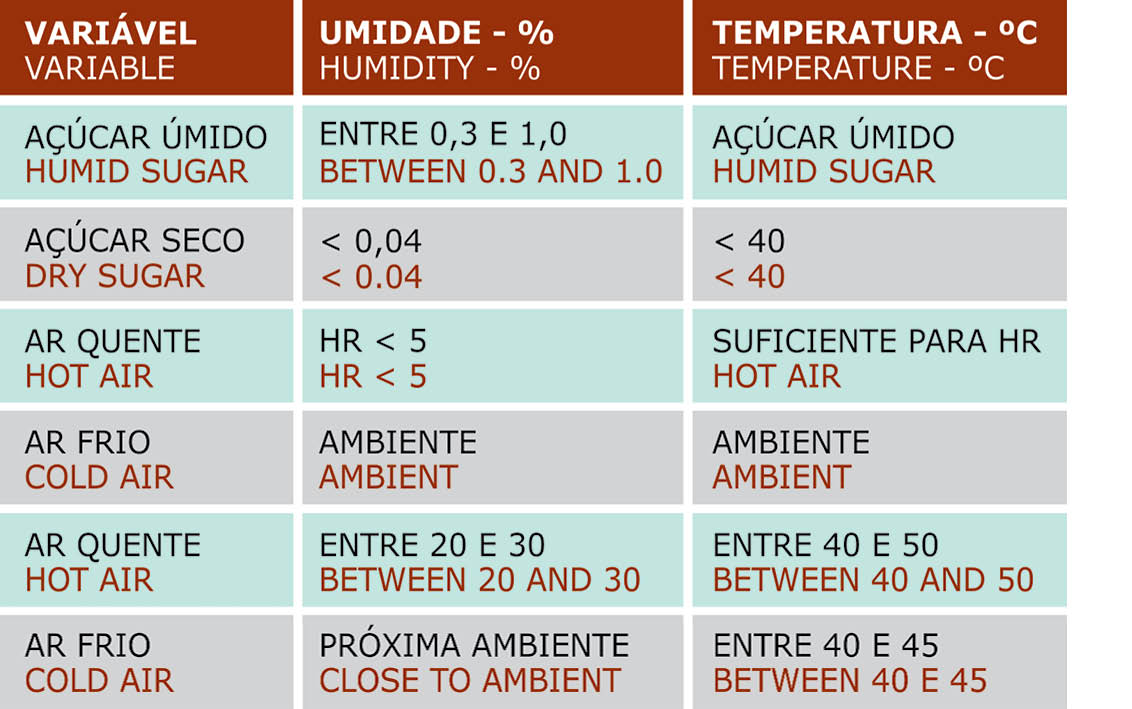

Control of thermodynamic air conditions is essential for the operation and assessment of the dryer. To that end, the unit should have the measures as variables detailed in the table. Observe that we did not show the hot air temperature, but rather the relative humidity.

What removes water from humid sugar is the hot air’s capacity to absorb water, and this depends on the difference of the relative humidity of hot air upon entry to and exit from the dryer, requiring the installation of hot air humidity sensors, both at the entrance and at the exit point. Types of dryers: normally, one operates with conventional dryers.

• in cascade with the direct passage of air;

• in cascade with the removal of air in the intermediary area;

• Buttner trays: dryer suited for low granulometry sugar;

• roto-Louvre: fluid bed type, with the passage of all the air through the sugar layer. This works for drying and cooling, allows regulating the layer height, adjusting retention time, and controlling air flow. It also allows removing the fine material without carrying over the crystals, which allows to later perform a conditioning operation; and,

• fluid-bed: static dryer, with real operation as fluidized bed. Excellent for high quality sugar.

A current example are the two refineries we installed on Maurice Islands, from where the entire refined product output is exported to Germany, where it is packed directly, with no further treatment. The installation guarantees that final humidity is below between 0.04 and 0.05% (Karl Fisher). These values are less than the 0.02% achieved when treated in an oven.