Weber Geraldo Valério

Director of Consult Agro

Op-AA-24

Adoption of new technologies

The development and implementation of new technologies has allowed for considerable gains in the sugar-based energy industry. New production models, such as for service outsourcing, are being adopted in all phases of sugarcane production. Regardless of whether this is just a vogue, companies have resorted to outsourcing as a means to meet three requirements: productivity, quality and hence, competitiveness in the market.

With respect to the sugarcane production process, one can see that outsourcing has been experimented in all phases, from the installation of the sugarcane plantation to the harvesting. However, the phase viewed as one of the most technical consists of applying pesticides (herbicides, maturators, nematicides, insecticides, etc.).

Managing weed requires rational control and should be seen from a new perspective, given that one may consider that excellence of results is anchored in the balance between the lack of competing weed and phytotoxicity of the culture, in an economic and safe manner. New plant varieties, changes in floristics, cultivars sensitive to herbicides, applications in different seasons (including the dry season) under adverse climate conditions, and physical and chemical herbicide characteristics, are factors that must be considered, in addition to other technologies that may reduce losses in applications, without affecting the end result. When such activities are outsourced, the service provider must be knowledgeable of such factors and must be in full control of logistics, equipment and people man-agement.

People management: People doing the planning must interact to seek the best strategy for each specific situation. The people directly involved in applications must be committed to them, i.e., it does not suffice to be a good machine operator, one must get involved in the process.

People management: People doing the planning must interact to seek the best strategy for each specific situation. The people directly involved in applications must be committed to them, i.e., it does not suffice to be a good machine operator, one must get involved in the process.

Logistics: Control over this factor allows interfering in the right moment. With respect to weed control, to look for applications before the culture and weed develop, is increasingly becoming a priority because of gains achieved with selectivity and savings, and hence, with productivity and reduction in final cost.

Equipment: A wrong selection of application equipment (machine/equipment) may have unwanted results, including the increase in costs. The model must be adapted to local characteristics, such as topography, alignment of stands, the need for maneuvering, climate conditions and others.

Studies show that the biggest losses relate to equip-ment and drift and may reach 50%, an extremely high percentage. Recent field work confirms such losses. To diagnose such losses during applications, to interpret them, and to find a solution for them, is mandatory. We have two bottlenecks that cause losses, and hence, reduction in efficiency and efficacy in spraying: improving distribution and bringing the active ingredient to its destination. Some factors may greatly contribute to the reduction of losses, improving distribution and how the active ingredient reaches its destination: the state of the tips; the type of tips (droplet size); spacing between tips; barring equipment: vertical and horizontal balance; dealing with climate conditions (relative humidity, temperature, wind speed); speed at which the application equipment moves forward; use of specific helpers.

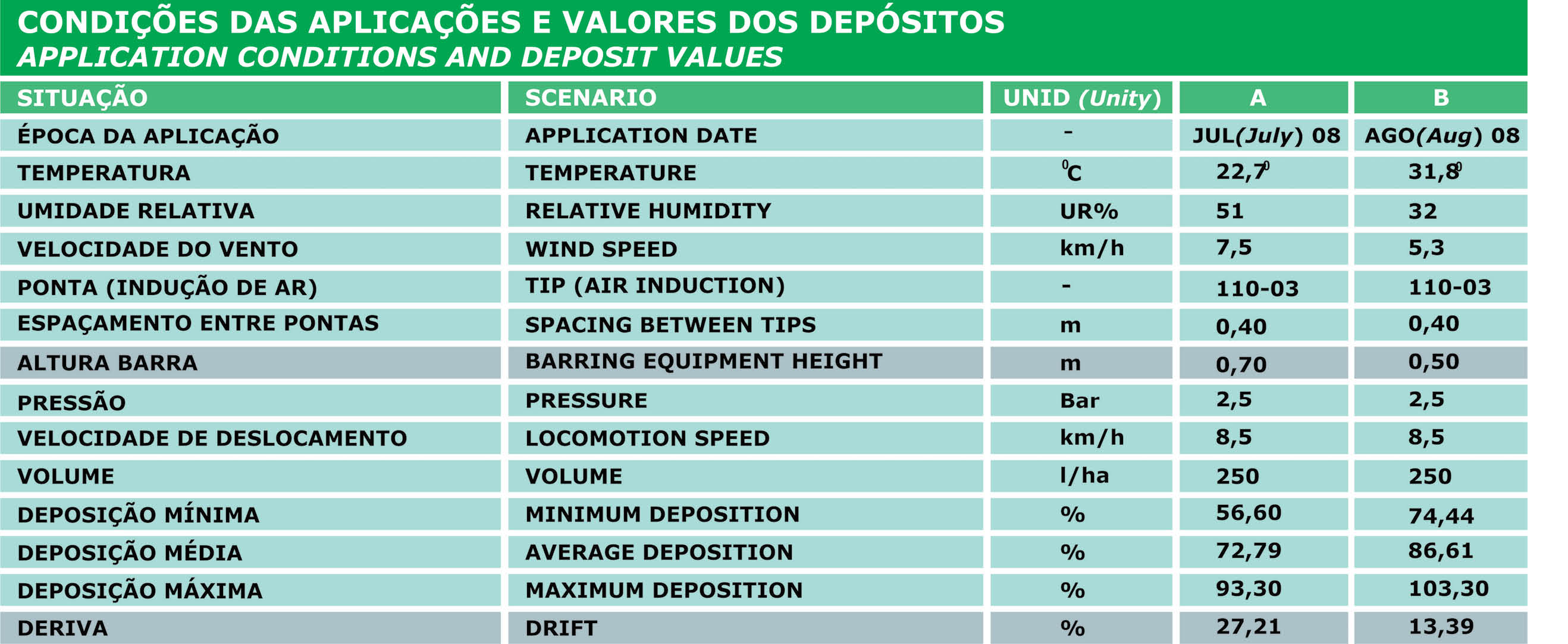

The table below shows an example of loss reduction. The main study factor was the distance from tip to target (barring equipment height), in two scenarios. The study shows the importance of the distance between the barring equipment and the target. In scenario B, even with unfavorable climate conditions, there was less drift. Studies attest to loss reductions when one influences droplet sizes, the spacing between tips, the use of helpers, the locomotion speed in relation to climate conditions, among others. Rational handling of weed has achieved significant gains. This justifies more attention and investment in the activity.